Production Introduction

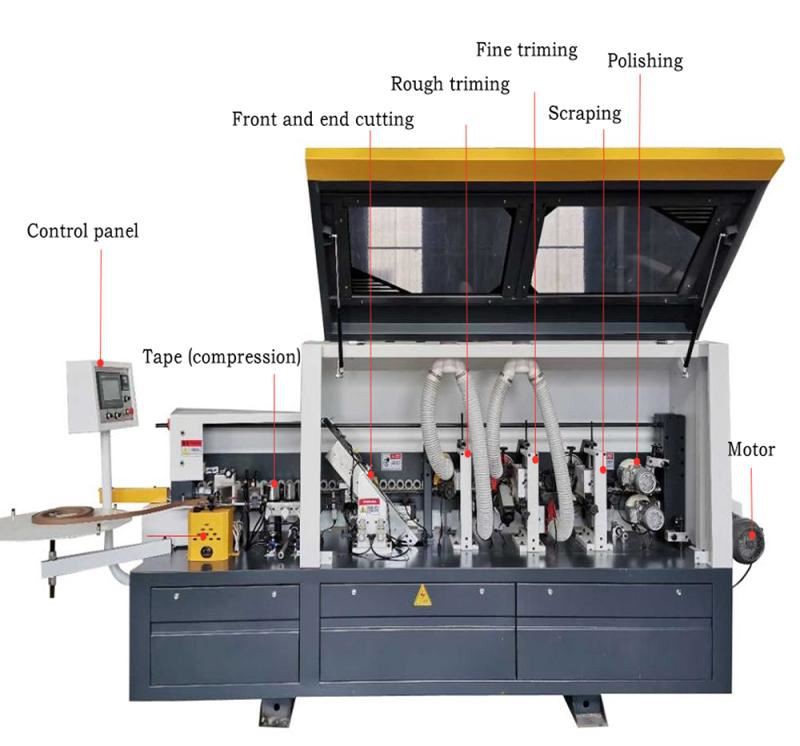

| In the production of panel furniture, edge banding is the most important and frequently used process. Edge banding can effectively improve the appearance quality of the furniture, avoid damage and deformation of the corners of the furniture during transportation and use, and can also be harmful when closed. The release of gas. The sawed end face of the board in the panel furniture must be protected and beautified by the edge banding. The automatic linear edge banding machine is a device that seals the edge banding materials such as solid wood and PVC to the edge of the board. The equipment applies molten hot melt adhesive to the end face of the board, and then presses the edge sealing material on the board. The hot melt adhesive rapidly solidifies to form an adhesive force, which binds the edge sealing material to the board. After that, it is necessary to go through such links as end cutting, trimming, scraping, polishing, sanding, etc., so that the end face of the plate can be protected beautifully. |

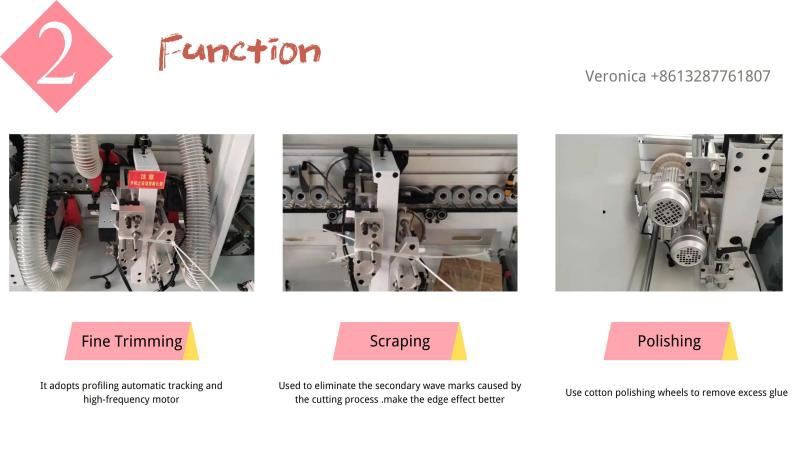

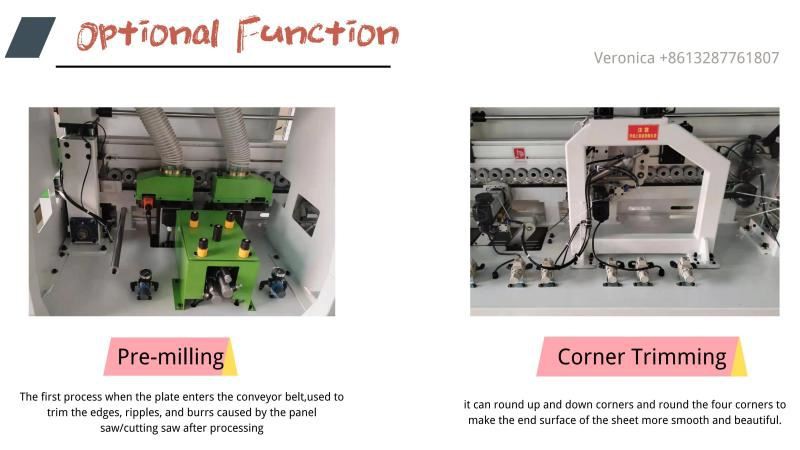

Due to the high degree of automation, the high precision and beautiful appearance of the processed plates, the automatic edge banding machine has gradually replaced the semi-automatic or manual edge banding machine. It includes glue sealing, front and rear trimming, rough trimming, scraping, polishing, and pre-milling, tracking, and grooving can be added as required. It is suitable for medium density fiberboard, blockboard, solid wood board, particle board, and plywood. Wait for straight edge banding and trimming. The fully automatic edge banding machine can make the board complete the procedures of gluing, edge sealing and gluing, front and rear truncating, upper and lower edge alignment, chamfering, scraping and sanding in one feeding process on the edge banding machine. Each feeding process can complete a straight edge operation. The continuity of each process is very strong, so the edge sealing efficiency is very high. |

|

Mode | GD2400 |

|

Size | 4200*900*1600 | |

Weight | 1300kg | |

Total power | 8.5kw | |

Width of banding | 12-60mm | |

Edge thickness | 0.4-3mm | |

work thickness | 10-55mm | |

Minimum length of sheet | 80mm | |

Minimum width of sheet | 80mm | |

Plate transport speed | 18m/min | |

Air Pressure | 0.6MPa-0.8Mpa | |

Heating power of rubber box | 1.8Kw | |

Rubber box transmission power | 0.55Kw | |

Homogeneous motor power | 0.37Kw*2 12000r/min.200Hz | |

Rough repair motor power | 0.75Kw*2 18000r/min.300Hz | |

Finishing motor power | 0.75Kw*2 18000r/min.300Hz | |

Polishing motor power | 0.18Kw*2 | |

Plate preheating power | 0.3Kw | |

Conveyor motor wattage | 1.5Kw |

|

|

| The automatic edge banding machine includes the body, each processing department group and the control system. During operation, it is necessary to ensure that the edge banding strip and the end surface of the board are firmly and smoothly combined, and the joint between the sealed surface and other surfaces cannot be exposed or collapsed, and the transition is natural and smooth. |

Hot Tags: woodworking pvc mdf automatic wood edge bander machine, China, suppliers, manufacturers, factory, price, wholesale, for sale, Semi Auto Edge Bander, PVC Edge Bander, Full Auto Edge Bander, Automatic PVC Edge Bander, Wood Edge Banding Machine, Edge Bander