Products Description

Machine Function Introduction

-

Preheating: the function of heating the plate before gluing so that it can be more firmly adhered to the edge banding belt after gluing

-

Pre-milling:processing the end face of the plate can avoid some defects of the saw.

-

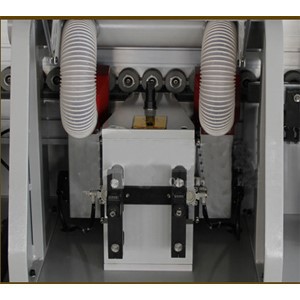

Flanging: apply the edge banding tape to the plate and press it tightly.

-

Trim: trim is a function that includes coarse trim, fine trim, profiling trim and edge scraping. Its function is to trim the edge banding around the board that is higher than the board surface, so that the board edge is too smooth and excessive to achieve the purpose of beautification.

-

Polishing: use soft materials to polish the cloth wheel to throw out the luster of the working surface to achieve better results

-

Edge cutting: cut off the excess edge banding belt before and after edge banding to make the edge banding belt flush with the end face of the plate

Edge banding machine is a thermoplastic processing equipment, which can process all straight and curved edges into edges with limited performance and shape to meet special requirements such as decoration or tensile strength.

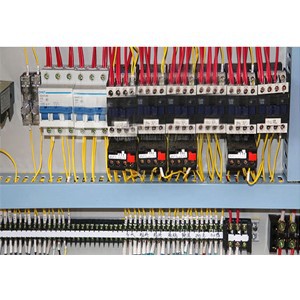

The edge banding machine is generally composed of motor, vacuum suction device, thermoplastic tape rack, mold, control circuit and other components. Its main principle is to process the edge into limited performance and shape through thermoplastic tape. Thermoplastic tape has certain heat resistance. It can be stretched under heating and hardened under cooling.

The working principle of the edge banding machine is: first, the motor will send the processed material into the edge banding machine, and then the vacuum suction device will adsorb the material on the workbench. After that, the worktable moves the material to the thermoplastic tape rack, and the control circuit will heat the thermoplastic tape. When the temperature reaches a certain temperature, the thermoplastic tape will be stretched, and the edge will be processed into the established performance and shape, and then cooled and fixed. Finally, the thermoplastic tape rack moves, and the material exits from the edge banding machine.

The edge banding machine has many advantages, the most important of which is easy to operate. One edge banding machine can handle various shapes of edges, and its processing speed is much faster than manual work. It can realize mass production and greatly improve the output. In addition, the operation of the edge banding machine is simple. You only need to set the parameters in advance, and then press the start key to complete the processing. The whole process is very convenient

The edge banding machine is widely used. It can be used in the woodworking industry, construction industry, furniture industry and electronic industry. In these industries, it can greatly save production costs and improve production efficiency. In addition, edge banding machines can also be used in the production of kitchen supplies, such as kitchenware, tableware, coffee pots, etc., to improve their appearance and quality

Hot Tags: artificial board automatic edge banding machine, China, suppliers, manufacturers, factory, price, wholesale, for sale, Edge Bander, Wood Edge Banding Machine, PVC Edge Bander, Automatic Edge Banding Machine, Semi Auto Edge Bander, Automatic PVC Edge Bander