Products Description

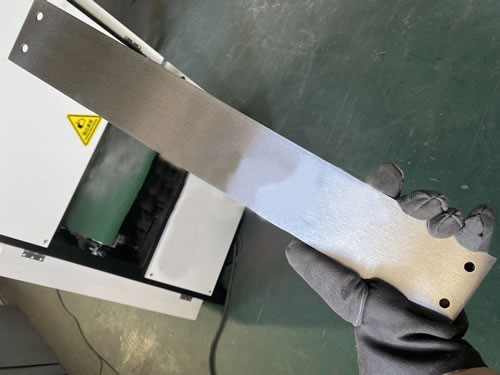

Sanding and polishing refer to a method of physically removing materials and objects that are uneven, uneven in thickness, and do not meet the process requirements, such as sandcloth, grinding wheel, sandpaper, cleaning cloth, and non-woven cloth polishing wheel, to make them more smooth, even, and consistent in thickness. The process is used for deburring, wire drawing, polishing, and other treatments on different surfaces of parts.

After the machine starts and operates normally according to the normal program, the ground slab is first fed to the upper and lower coarse sand rollers through the limit plate device and conveyor roller at the right end of the machine. The high-speed rotating sand belt simultaneously grinds the upper and lower sides of the slab to achieve constant thickness grinding. Finally, the remaining surface dust is removed through the discharge end and sent out of the machine.

The sand frame components are mainly composed of contact rollers, tensioning rollers, guide rollers, grinders, tensioning cylinders, sand belt movement devices, crossbeams, sand belts, and bearing seats, which are the core components of the sanding machine to achieve the main cutting motion.

Purpose: The double-sided broadband thickness sanding machine is an efficient and powerful broadband sanding machine designed and manufactured on the basis of the production of double-sided broadband sanding machines. This machine is mainly used for fixed thickness grinding, coarse sand and finishing grinding, and fine sand grinding of artificial boards. Sanding the surface of particle board, medium density fiberboard, gypsum particle board or other wood-based panels makes the thickness precision and surface roughness meet certain requirements. For example, requirements for secondary processing.

Our Advantage

1. Good grinding effect: The metal sanding machine uses high-strength and wear-resistant materials such as aluminum alloy and stainless steel, and uses high-speed rotating grinding wheels to remove surface oxidation layers, corrosion, scratches, and burrs, making the metal surface smoother.

2. High production efficiency: As a professional metal processing equipment, metal sanding machines can complete a large amount of metal grinding processing in a short time, improving production efficiency and saving human and material resources.

3. Easy to operate: In addition to safety protection devices, the metal sanding machine is easy to operate and use. As long as the type of grinding wheel and grinding parameters are selected according to requirements, operations such as clamping, adjusting, starting, and stopping can be carried out.

4. Low cost: One of the advantages of metal sanding machines is that their prices are relatively favorable. Compared to other metal processing equipment, they have a higher cost-effectiveness and are suitable for use by small and medium-sized enterprises or individuals.

5. Strong plasticity: Metal sanding machines are suitable for different types, materials, and shapes of metal products, and are not limited by their surface treatment processes. They have strong adaptability and are widely used in the metal processing industry.

|

|

|

|

Hot Tags: metal water polishing machine sander, China, suppliers, manufacturers, factory, price, wholesale, for sale, Wood Polish Machine, Wood Floor Polish Machine, Wood Furniture Polishing Machine, Sander Polisher Machine, Furniture Polishing Machine, Polish Machine