Guandiaocnc

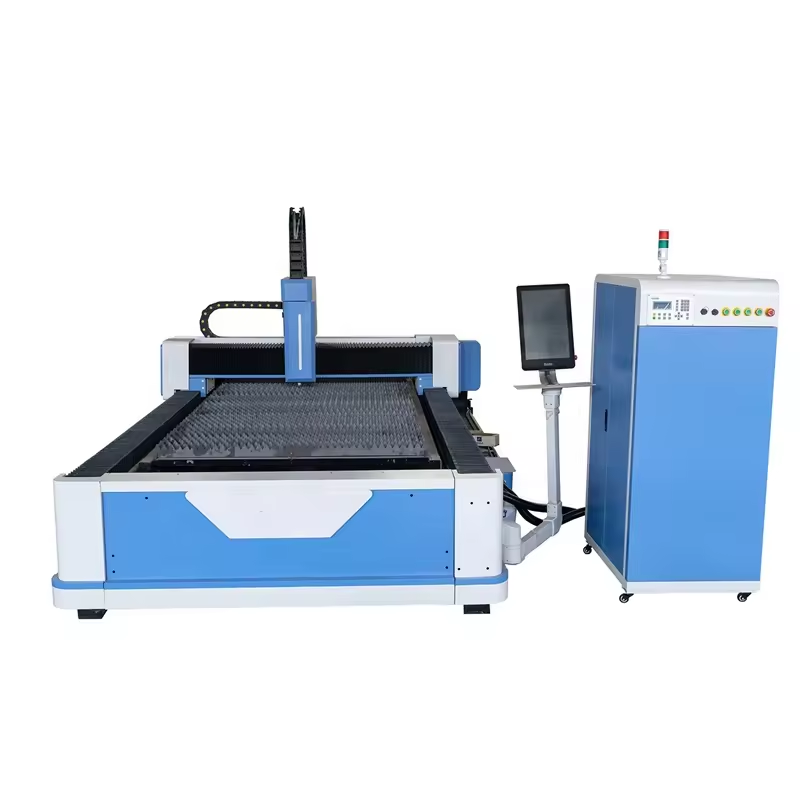

# High-Performance Fiber Laser Cutting Machine: Precision & Efficiency Redefined

As a cutting-edge CNC processing equipment integrating advanced **fiber laser technology**, **CNC technology**, and precision mechanical technology, the **Fiber Laser Cutting Machine** has become the core choice for modern metal processing industries. It delivers exceptional cutting performance through non-contact processing, bringing revolutionary upgrades to production efficiency, product quality, and cost control for manufacturers worldwide.

---

### Core Working PrincipleThe machine utilizes a high-power **fiber laser generator** as the light source, producing a laser beam with a wavelength of 1064nm that features excellent absorption by metal materials . This high-energy density laser beam is focused into an ultra-fine spot (minimum diameter less than 0.1mm) via the cutting head, instantly melting and vaporizing the irradiated area of the workpiece . Guided by the intelligent CNC system, the laser spot moves linearly relative to the workpiece, forming continuous narrow slits to achieve automatic and precise cutting of complex 2D or 3D patterns .

---

### Outstanding Advantages1. **Superior Cutting Quality**: The kerf width is only 0.1-0.2mm, with a small heat-affected zone and no mechanical deformation . The cutting surface is smooth and burr-free, with surface roughness up to 12.5μm, eliminating the need for secondary processing .

2. **High Cutting Speed**: Its speed is 4-5 times faster than YAG laser cutting machines, and even surpasses CO2 laser cutters . For example, a 2000W model cuts 8mm carbon steel at 1.6m/min and 2mm stainless steel at 3.5m/min .

3. **Energy-Saving & Cost-Effective**: The photoelectric conversion rate exceeds 30%, 10 times that of YAG lasers, significantly reducing power consumption . It only requires electricity (no additional gases) and has low maintenance costs due to a simple optical path and no need for mirror adjustment .

4. **Stable & Durable Performance**: Adopting semiconductor modular design, the laser resonator has no optical lenses, ensuring maintenance-free operation and high stability . The annealed steel bed and aviation-grade aluminum beam enhance structural rigidity and cutting precision .

5. **Flexible Processing Capacity**: It handles both flat and bevel cutting, and can achieve 3D cutting with a robotic arm . It supports various metal materials, including carbon steel, stainless steel, aluminum, copper, and titanium alloy .

---

### Wide Application FieldsThe **Fiber Laser Cutting Machine** is widely used in numerous manufacturing sectors, such as:- **Automotive Industry**: Cutting body parts, lightweight aluminum alloy components, and precision accessories .

- **Aerospace & Electronics**: Processing high-precision parts, circuit boards, and small metal casings .

- **Sheet Metal & Machinery**: Customized production of hardware products, mechanical parts, and structural components .

- **Architecture & Furniture**: Cutting decorative metal materials, pipe profiles, and customized furniture components .

Whether for mass production or custom processing, this machine perfectly meets the diverse needs of high-precision, high-efficiency metal cutting, helping enterprises enhance market competitiveness and achieve sustainable development.

As a cutting-edge CNC processing equipment integrating advanced **fiber laser technology**, **CNC technology**, and precision mechanical technology, the **Fiber Laser Cutting Machine** has become the core choice for modern metal processing industries. It delivers exceptional cutting performance through non-contact processing, bringing revolutionary upgrades to production efficiency, product quality, and cost control for manufacturers worldwide.

---

### Core Working PrincipleThe machine utilizes a high-power **fiber laser generator** as the light source, producing a laser beam with a wavelength of 1064nm that features excellent absorption by metal materials . This high-energy density laser beam is focused into an ultra-fine spot (minimum diameter less than 0.1mm) via the cutting head, instantly melting and vaporizing the irradiated area of the workpiece . Guided by the intelligent CNC system, the laser spot moves linearly relative to the workpiece, forming continuous narrow slits to achieve automatic and precise cutting of complex 2D or 3D patterns .

---

### Outstanding Advantages1. **Superior Cutting Quality**: The kerf width is only 0.1-0.2mm, with a small heat-affected zone and no mechanical deformation . The cutting surface is smooth and burr-free, with surface roughness up to 12.5μm, eliminating the need for secondary processing .

2. **High Cutting Speed**: Its speed is 4-5 times faster than YAG laser cutting machines, and even surpasses CO2 laser cutters . For example, a 2000W model cuts 8mm carbon steel at 1.6m/min and 2mm stainless steel at 3.5m/min .

3. **Energy-Saving & Cost-Effective**: The photoelectric conversion rate exceeds 30%, 10 times that of YAG lasers, significantly reducing power consumption . It only requires electricity (no additional gases) and has low maintenance costs due to a simple optical path and no need for mirror adjustment .

4. **Stable & Durable Performance**: Adopting semiconductor modular design, the laser resonator has no optical lenses, ensuring maintenance-free operation and high stability . The annealed steel bed and aviation-grade aluminum beam enhance structural rigidity and cutting precision .

5. **Flexible Processing Capacity**: It handles both flat and bevel cutting, and can achieve 3D cutting with a robotic arm . It supports various metal materials, including carbon steel, stainless steel, aluminum, copper, and titanium alloy .

---

### Wide Application FieldsThe **Fiber Laser Cutting Machine** is widely used in numerous manufacturing sectors, such as:- **Automotive Industry**: Cutting body parts, lightweight aluminum alloy components, and precision accessories .

- **Aerospace & Electronics**: Processing high-precision parts, circuit boards, and small metal casings .

- **Sheet Metal & Machinery**: Customized production of hardware products, mechanical parts, and structural components .

- **Architecture & Furniture**: Cutting decorative metal materials, pipe profiles, and customized furniture components .

Whether for mass production or custom processing, this machine perfectly meets the diverse needs of high-precision, high-efficiency metal cutting, helping enterprises enhance market competitiveness and achieve sustainable development.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb